Custom Plastic Panels:

Universal Plastics has a long history of expertise in manufacturing thermoformed plastic panels. Contact us today to discuss your ideas.

Universal Plastics is the largest precision heavy gauge custom thermoformer in the Northeastern US with an asset base of 22 pressure formers, 14 vacuum formers and 26 5-axis trimming machines, supplying our customers with vacuum forming, pressure forming, including twin sheet forming and complex assemblies, with part sizes up to 12’ x 9’. In addition, we offer in-house tooling and a full complement of secondary/finishing services, including our new state of the art paint booths which can produce automotive quality finishes. With a range of rotary formers, rapid manufacturing processes, and a global supply chain, we can produce thermoformed plastic panels at the most competitive prices.

In addition to custom thermoforming, Universal Plastics also offers injection molding (including gas assist and structural foam molding) and custom blow molding. We would be glad to talk with you about the optimal process for your needs.

Medical Plastic Panels:

- Covers for equipment

- Sidewalls

- User interface panels

- Enclosures

- Bezels

- Plastic panels for hospital rooms

Industrial Thermoformed Panels:

- User interfaces

- Bezels

- Enclosures

- Plastic housings

- Panels

Miscellaneous Thermoformed Plastic Panels:

Universal has a long history of experience in and extensive knowledge of manufacturing high quality heavy gauge thermoformed plastic panels. In addition to our expertise in medical and industrial markets, Universal has worked with a range of customers to design custom thermoformed plastic panels for a variety of applications, including:

- Bins, totes and bases

- Office furniture and interior panels

- Plastic enclosures for fitness equipment

- Plastic enclosures for fitness equipment

- Marine vehicle parts

- Transportation components, plastic covers and enclosures

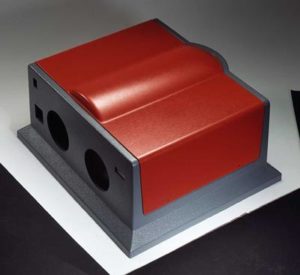

Custom thermoformed plastic enclosures allow a combination of a complex molded geometry with a stylish finished look with relatively low tooling cost. Thermoformed or vacuum formed plastic panels also provide a better finish than fiberglass molded or stamped metal.

Thermoformed Plastic Trays Expertise at Universal Plastics:

Universal Plastics has a long history of expertise in manufacturing thermoformed plastic trays. Whether you need a custom plastic tray in low volume or high volume, contact us today to discuss your ideas.

Universal Plastics is the largest precision heavy gauge custom thermoformer in the Northeastern US with an asset base of 22 pressure formers, 14 vacuum formers and 26 5-axis trimming machines, supplying our customers with vacuum forming, pressure forming, including twin sheet forming and complex assemblies, with part sizes up to 12’ x 9’. In addition, we offer in-house tooling, an experienced engineering staff, and a full complement of secondary/finishing services, including our new state of the art paint booths which can produce automotive quality finishes. With a range of rotary formers, rapid manufacturing processes, and a global supply chain, we can produce thermoformed parts at the most competitive prices.

In addition to custom thermoforming, Universal Plastics also offers injection molding (including gas assist and structural foam molding) and custom blow molding. We would be glad to talk with you about the optimal process for your needs.