UNIVERSAL PLASTICS IS A PLASTICS PROCESSOR SPECIALIZING IN CUSTOM THERMOFORMING, INJECTION MOLDING AND BLOW MOLDING.

Our expertise lies in manufacturing large, complex, highly aesthetic parts.

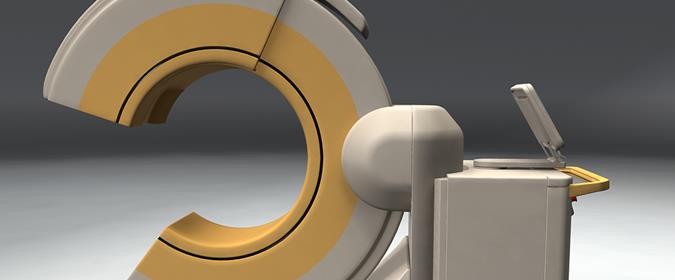

MEDICAL PARTS

Universal Plastics specializes in plastic medical parts, and has experience working with customers ranging from large medical device OEMs to venture-funded technology start-ups. Diagnosis, optometrist, laboratory, birthing and more parts.

LARGE AESTHETIC PARTS

Universal Plastics has a solution for large plastic parts with complex designs and excellent cosmetics. We specialize in large plastic enclosures, medical equipment covers, kiosk covers, bezels, skins, handles, and other customer facing parts.

PLASTIC TRAYS

Universal Plastics has expertise in manufacturing thermoformed & molded plastic trays for a variety of end-uses including shipping trays, material handling trays, dunnage and packaging trays, etc.

IN-HOUSE PAINTING

Our in-house painting capabilities allow your part to be manufactured at one location. We offer class A automotive quality high gloss painting services, with state-of-the-art paint booths capable of handling part sizes up to 11’x11’x3′.

COMPLEX ASSEMBLIES

Our highly experienced manufacturing team can execute higher level assembly of plastic parts including sonic welding, stake heating, inserts, masking, trimming, pad printing, labeling and more.

ENGINEERING AND TOOLING

Universal Plastics’ talented group of in-house Engineers bring a depth of expertise and our end-to-end capabilities to meet all your needs from product concept to manufacturing.