Universal Plastics offers design engineering services and tooling expertise to partner with you every step from concept to manufacturability. Our award-winning and talented engineering department has extensive experience in product design and execution. Our in-house tooling department offers a range of capabilities including tool-making (for custom thermoforming), tool preventative maintenance, and a seamless tool transfer process.

Engineering & Design

Universal Plastics provides engineering services for custom thermoforming, blow molding and injection molding (including gas assist injection molding and structural foam molding) to assist customers in the development of large plastic parts. We have 18 engineers on staff to partner with you through the design & production process, including:

Product design consultation: Universal Plastics engages the customer at the concept stage of the design process to educate the customer on their freedom to exceed former limitations on part size, design complexity, and cosmetic appearance. By partnering, we can work with you to consolidate many smaller parts originally intended to be assembled into one larger part with a cleaner profile, thereby improving the aesthetic appeal of the entire unit and reducing subsequent processing. Whether you need to fine-tune your drawing, prototype design, or complete conceptualization and visualization tools, we can work with you to develop your custom plastic product – on time and within your budget, ready for your approval.

Project management: Universal Plastics offers three manufacturing processes on state-of-the-art equipment in 4 locations. This enables us to recommend the optimum production process and equipment for every part. Though Universal Plastics is renowned for its expertise in medium to larger sized parts, we produce parts of all sizes, and customers with large multicomponent projects chose Universal Plastics to consolidate their supply bases.

Many customers have successfully launched new products that we sketched, rendered, modeled, designed, detailed, and validated to carry them through the product development cycle. Universal Plastics has a long legacy and deep experience in converting ideas into real products and making existing products work better. Universal Plastics assists our customers as a partner through every phase of the product development process so that we can produce the highest quality parts with the shortest possible lead time.

Contact us today to discuss how we can meet your needs.

In-House Tooling

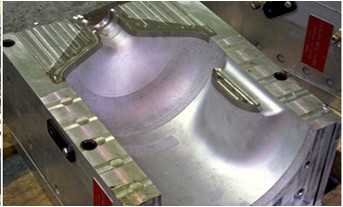

Universal Plastics can produce efficient production tooling for optimal or optimum product cost – from your ideas, drawings or other industry standard computer designs – by utilizing state-of-the-art software, engineering and machining equipment. Our mold and machine shop, along with our outside partners, ensures the best quality molds are built and maintained with the highest quality care. We are dedicated to quality from start to finish. For a full list of our equipment, please contact us.

Tool design consultation & management: in-house tooling design capabilities are essential in producing consistent, premium quality plastic parts. Universal Plastics’ engineers engage designers in the conceptual stage of the project to assure part and mold design compatibility, as well as design for manufacturability and production efficiency. Pro-Engineer and SolidWorks modeling systems verify all designs prior to any fabrication, eliminating costly tooling changes. All tooling is kept on an electronically tracked preventative maintenance schedule. The PM schedule is run through our ERP system to ensure that mold wear does not become a hindrance to production quality or part lead time. Being proactive in the design and maintenance of tooling prevents any manufacturing issues before they occur. To learn more about our tool PM program, please click here.

Tool transfer process: Universal Plastics has many decades of experience managing transfer mold projects. Universal Plastics’ comprehensive mold transfer program assures you that your parts will run smoothly in production on day one. Our engineers and project managers will reduce your mold transition uncertainties so you can get back to steady production. Contact us if you would like to discuss our Tool Transfer Procedure and Tool Transfer Checklist to get started.

Custom thermoforming tooling: our thermoforming tooling department includes 3 Haas Mold Maker machining centers and a Prototrack full three axis machining center, all MasterCam capable for full 3-D machining. We add to that a full complement of traditional wood and metal working equipment, including a welding shop. We take our greatest pride in making quality aluminum tools that deliver consistent quality products year after year. Our customers have come to know us as a company that can build quality tools that get the job done right the first time.

Advantages of Thermoforming Tooling: thermoforming tooling can be built from wood, composite, cast aluminum, or machined aluminum billet. Temporary molds are commonly built of wood or composites, which can be easily machined. Permanent tools are either machined or cast aluminum, depending on the depth of the tool. Aluminum molds are designed by CAD designers. Once designed, these mold designs are transferred to our CNC routers that produce the patterns required for the final mold. Thermoforming tools can be modified easily, so changes can be made quickly and for much less money than the hardened steel tooling typical of molded parts. We believe quality parts are a direct result of quality tools, and we take our greatest care in making quality machined or cast aluminum tools that deliver consistent quality products year after year. Our award-winning design, modern manufacturing facilities, warehousing and shipping services can bring your product to life in 8 -12 weeks and improve your bottom line with less initial investment and a superior commitment to your needs.

Universal Plastics Capabilities:

Universal Plastics is a plastics processor specializing in custom thermoforming, injection molding and blow molding. Our expertise lies in manufacturing large, complex, highly aesthetic parts. To read more about our 4 sites and capabilities, click here.